Hydraulic Transient Simulation Software

Interlink Systems, Inc. has spent many years developing and enhancing software to calculate the response of subsea hydraulic and electrohydraulic control systems. The old workhorse version of this software is called The Control Simulator, Version 4 (CS4). It is a DOS program that also runs well under Windows.

CS4 is still available, but it is being replaced by CSI (Control Simulator Innovations), a 32 bit version to run under Windows 95, 98, NT, 2000 and XP. All new development will be on CSI.

Both CSI and CS4 do a very good job of predicting pressures, flows, response times, and other transient effects in control systems made with steel tubing or thermoplastic hose. The length of the control lines does not affect the accuracy of the simulations. For more details, see the links at the left.

Water hammer, line packing, and other transients

The models developed for The Control Simulator are generally applicable to all subsonic transient liquid flow problems in pipes of any length. Related techniques could allow handling of suspended particles, flow separation, and other effects. If you have a need for custom software to simulate transient effects in pipelines, fire control systems, fuel injection systems, etc. I would be happy to talk to you about how this technology can be adapted to your problem.

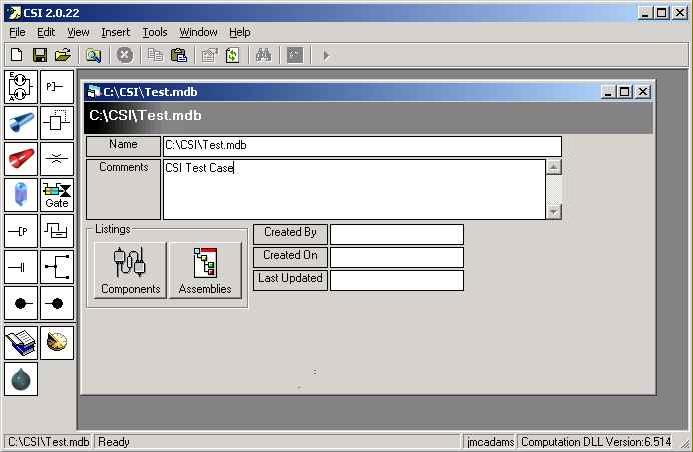

Control Simulator Innovations (CSI) for Windows

CSI collects all of the most used features of CS4 into an improved, modern application that runs under any 32-bit Windows operating system (95, 98, ME, 2000, NT, or XP). Among the improvements relative to CS4 are libraries for all components, plots of results, easy alteration of simulation files, and a greatly improved accumulator model (see The Precharge Calculator for details).

CSI is the current product supported for simulation of control systems. CS4 is frozen and will receive no further development.

A description of CSI is not yet on this site, but most of the models other than the accumulator are derived from CS4, so you can get an idea of what it does from reading the CS4 information. You may also download the operator's manual to look at.

The Control Simulator, Version 4 for DOS and Windows

Version

4 is designed to simulate systems in which a hydraulic power source is

connected to an end device via a metal or thermoplastic control line.

Though it will predict correct steady state conditions, The Control

Simulator is most useful in situations where transient flow conditions

dominate the response. Transient flow situations are

extremely

difficult to calculate by hand, but The control Simulator does it

quickly and accurately (see

comparisons with test data).

Version

4 is designed to simulate systems in which a hydraulic power source is

connected to an end device via a metal or thermoplastic control line.

Though it will predict correct steady state conditions, The Control

Simulator is most useful in situations where transient flow conditions

dominate the response. Transient flow situations are

extremely

difficult to calculate by hand, but The control Simulator does it

quickly and accurately (see

comparisons with test data).Example applications include: simple direct control of a production tree valve; the supply line to a multiplex hydraulic pod, including the accumulator and solenoid valve in the pod, and the valve actuator being controlled; and a supply line to a subsea hydraulic motor. Models to aid in the analysis of TFL systems are also included.

The kinds of control problems The Control Simulator is useful for include: valve actuator movement times in simple direct control systems; pressure dips on a multiplex hydraulic supply line; examining the difference in accumulator performance between land and subsea conditions; and doing sensitivity studies (on things such as the effects of flow restrictions) in order to anticipate problems with component selection.

It has been under development since the earliest version was completed in 1981. The latest version is 4.18h, January 2003. Since about 2002, development of CS4 has stopped in favor of expanding CSI, the new Windows version.

The Control Simulator is designed to be easy to use. In normal use, all options are selected from menus that include explanations of the models and options available. It accepts input and produces printed data in almost any desired unit of measure thereby avoiding tedious manual conversion between units.

The Control Simulator produces data in the form of a tabular printout on the printer (DOS only) or to a disk file. The first page contains all parameters input by the operator or calculated by the program which influence the simulation. Names of files used, date and time, and other useful data are also included. All important system variables such as pressures, flows, positions, etc. are available for printout as functions of time. The operator can choose to print or not print each of the variables on an individual basis. For those that are printed, the operator chooses the unit of measure and number of decimal places to use.

List of Simulated Devices

CS4 Output Example

Compare CSI and CS4

Mathematical Basis

The Control Simulator incorporates mathematical models of one-dimensional flow in hose and hard lines. The models are developed by writing partial differential equations describing the balance of forces and conservation of mass in a small segment of line. Then, using the method of characteristics, the partial differential equations are transformed into a system of two total differential equations. These are finally integrated and put into a finite difference form.

A complete simulation uses these finite difference equations in combination with initial conditions and boundary equations which describe the flow versus pressure characteristics of the devices on the ends of the line. This structure easily handles fluid compression, line expansion, inertial forces, time varying characteristics, and many other nonlinear relations that are difficult or impossible to calculate by hand.

The method of characteristics is a widely used and successful method of handling transient flow problems. The simpler equations used to model tubing have been used for a long time to model water hammer and other flow problems in water power distribution systems. The more complex equations for hose include terms that approximate the nonlinear, time-dependent viscoelastic expansion of thermoplastic hose.

The development of the basic equations used in The Control Simulator is described in the book Fluid Transients by E. Benjamin Wylie and Victor L. Streeter (see the Bibliography). Though the development of the models used in The Control Simulator extends far beyond the examples in the book, the material in the book is recommended reading for those who wish to know more about the basis and limitations of the modeling methods. Several applications are described in the book with some test results.